GlobalVox is heavily invested in ERP applications and has experience of nearly 2 decades witnessing evolution of ERP and opportunities in manufacturing domain.

The future of Enterprise Resource Planning (ERP) into manufacturing may be shaped by a variety of factors. Some potential trends that could influence the future of ERP in manufacturing include:

Overall, the future of ERP into manufacturing is likely to be shaped by a complex mix of factors, and it will be important for manufacturers to adopt and integrate new technologies and approaches to improve their operations, efficiency, and sustainability.

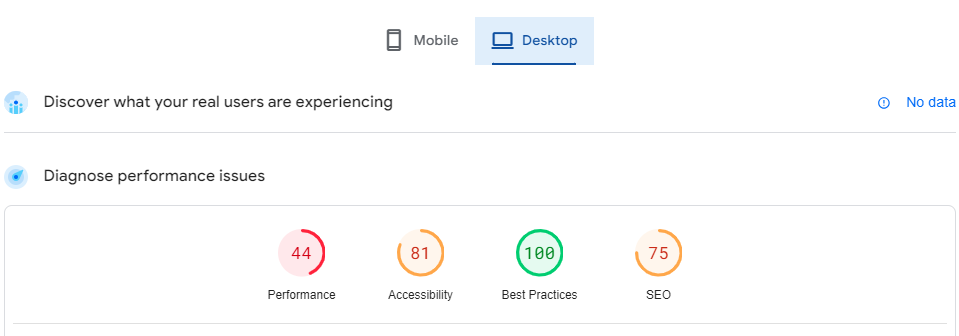

Integration with advanced technologies: ERPs are likely to become more integrated with advanced technologies such as the Internet of Things (IoT), machine learning, and artificial intelligence (AI) to enable real-time data capture and analysis, predictive maintenance, and proactive decision-making.

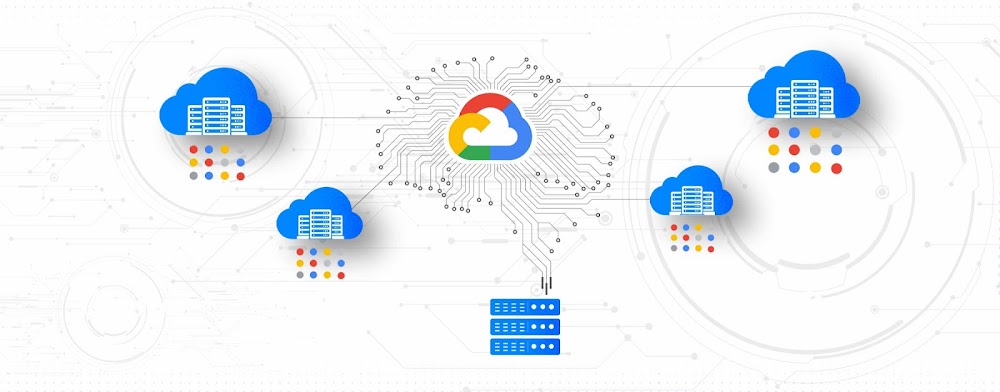

Cloud-based ERP: Cloud-based ERP systems are gaining popularity among manufacturers due to their scalability, flexibility, and cost-effectiveness. This trend is likely to continue as more manufacturers adopt cloud-based ERP solutions.

Mobile ERP: Mobile ERP solutions, which enable employees to access data and perform tasks from anywhere, are likely to become more prevalent in manufacturing. This trend is driven by the increasing use of mobile devices in the workplace and the need for real-time data access.

Increased focus on supply chain management: ERPs are expected to become more integrated with supply chain management systems to enable better coordination and visibility across the entire supply chain.

Emphasis on sustainability: Manufacturers are increasingly focused on sustainability and reducing their environmental footprint. ERPs are expected to become more integrated with sustainability metrics and reporting to help manufacturers track and improve their environmental performance.